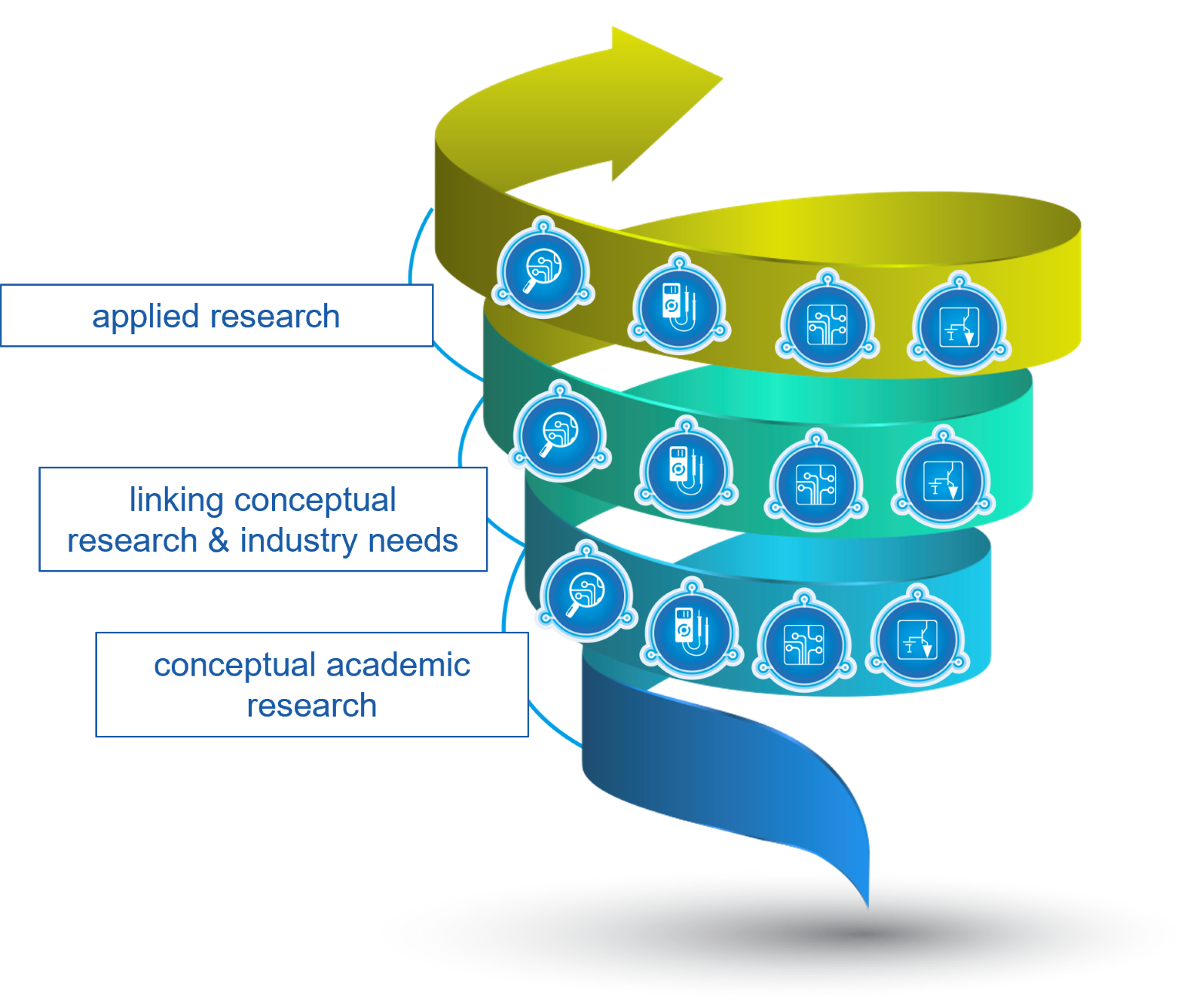

MICAS is unique in the broad range of research activities it focuses on, spanning from conceptual blue-sky research, over applied research, up to partner specific industrial research. In each phase of this pipeline, the research goes through all steps in the design cycle: from system-level conceptualization and architecting, over chip and sensor design and implementation, to fabrication, packaging and characterization. In this way, the initial idea spirals upward until it reaches its final goal: creating impact, both at the academic and at the socio-economical level.

In its research portfolio, MICAS has a range of long-term and visionary academic research ideas, typically supported by funding from KU Leuven and the Flanders Research Foundation (FWO). This research is typically 15 years ahead of industrial products.

MICAS is also strong in taking its conceptual research results a step closer to the needs of industry. In this phase, the academic research results are benchmarked against the roadmaps of industry to identify a match, and to steer the research in the right direction. In this phase, collaborative fundamental research projects, such as with the Institute for the Promotion of Innovation by Science and Technology in Flanders (IWT), European H2020 or Industrial R&D research projects initiate the collaborations with international industry.

Finally, MICAS also engages in a next step in the research pipeline to create and transfer technology and knowledge. Hence we work closely with various R&D divisions in the international industry via direct, bilateral research collaborations. This makes it possible to conduct research on well-defined and tightly tailored research topics, in order to achieve a breakthrough and technology transfer within a short to medium (5 years) timeframe. In some cases, this transfer materializes through the creation of a spin-off with the support of MICAS.

The design cycle starts with an innovative idea, which is extensively assessed, simulated and benchmarked at system level. Gradual refinement converts this concept into an implementable architecture.

MICAS strives to, again and again, effectively turn these concepts into measurable chips. This is supported by strong investments in design tools, access to the latest chip technologies and technical support. This is crucial success, as we firmly believe that real-life silicon is necessary to validate our results.

MICAS has a unique and excellent chip measurement lab (ranging from DC to THz and optical), sensor testing facilities, equipment for state-of-the-art chip packaging (flip-chip and wirebonding) and chip repair (laser cutting and FIB repair), as well as skilled technicians to provide necessary support support.

The analysis of these measurement results of our chips brings new insights. Insights, which again form the starting-point for a new design cycle, towards the next generation of chips.

Learn more about how we can collaborate.